Godzilla x Kong: The New Empire (2024)

Following their explosive showdown, Godzilla and Kong must reunite against a colossal undiscovered threat hidden within our world, challenging their very existence – and our own.

Kung Fu Panda 4 (2024)

Po is gearing up to become the spiritual leader of his Valley of Peace, but also needs someone to take his place as Dragon Warrior. As such, he will train a new kung fu practitioner for the spot and will encounter a villain called the Chameleon who conjures villains from the past.

Dune: Part Two (2024)

Follow the mythic journey of Paul Atreides as he unites with Chani and the Fremen while on a path of revenge against the conspirators who destroyed his family. Facing a choice between the love of his life and the fate of the known universe, Paul endeavors to prevent a terrible future only he can foresee.

No Way Up (2024)

Characters from different backgrounds are thrown together when the plane they're travelling on crashes into the Pacific Ocean. A nightmare fight for survival ensues with the air supply running out and dangers creeping in from all sides.

Migration (2023)

After a migrating duck family alights on their pond with thrilling tales of far-flung places, the Mallard family embarks on a family road trip, from New England, to New York City, to tropical Jamaica.

Damaged (2024)

A Chicago detective travels to Scotland after an emerging serial killer’s crimes match those that he investigated five years earlier, one of which was the crime scene of his murdered girlfriend.

Breathe (2024)

Air-supply is scarce in the near future, forcing a mother and daughter to fight for survival when two strangers arrive desperate for an oxygenated haven.

The Wages of Fear (2024)

When an explosion at an oil well threatens hundreds of lives, a crack team is called upon to make a deadly desert crossing with nitroglycerine in tow.

Rebel Moon - Part Two: The Scargiver (2024)

The rebels gear up for battle against the Motherworld as unbreakable bonds are forged, heroes emerge — and legends are made.

Madame Web (2024)

Forced to confront revelations about her past, paramedic Cassandra Webb forges a relationship with three young women destined for powerful futures...if they can all survive a deadly present.

Woody Woodpecker Goes to Camp (2024)

After getting kicked out of the forest, Woody thinks he's found a forever home at Camp Woo Hoo — until an inspector threatens to shut down the camp.

Civil War (2024)

In the near future, a group of war journalists attempt to survive while reporting the truth as the United States stands on the brink of civil war.

The Tearsmith (2024)

Adopted together after a tough childhood in an orphanage, Nica and Rigel realize that unexpected but irresistible feelings pull them together.

Dune (2021)

Paul Atreides, a brilliant and gifted young man born into a great destiny beyond his understanding, must travel to the most dangerous planet in the universe to ensure the future of his family and his people. As malevolent forces explode into conflict over the planet's exclusive supply of the most precious resource in existence-a commodity capable of unlocking humanity's greatest potential-only those who can conquer their fear will survive.

Land of Bad (2024)

When a Delta Force special ops mission goes terribly wrong, Air Force drone pilot Reaper has 48 hours to remedy what has devolved into a wild rescue operation. With no weapons and no communication other than the drone above, the ground mission suddenly becomes a full-scale battle when the team is discovered by the enemy.

Heart of the Hunter (2024)

A retired assassin is pulled back into action when his friend uncovers a dangerous conspiracy at the heart of the South African government.

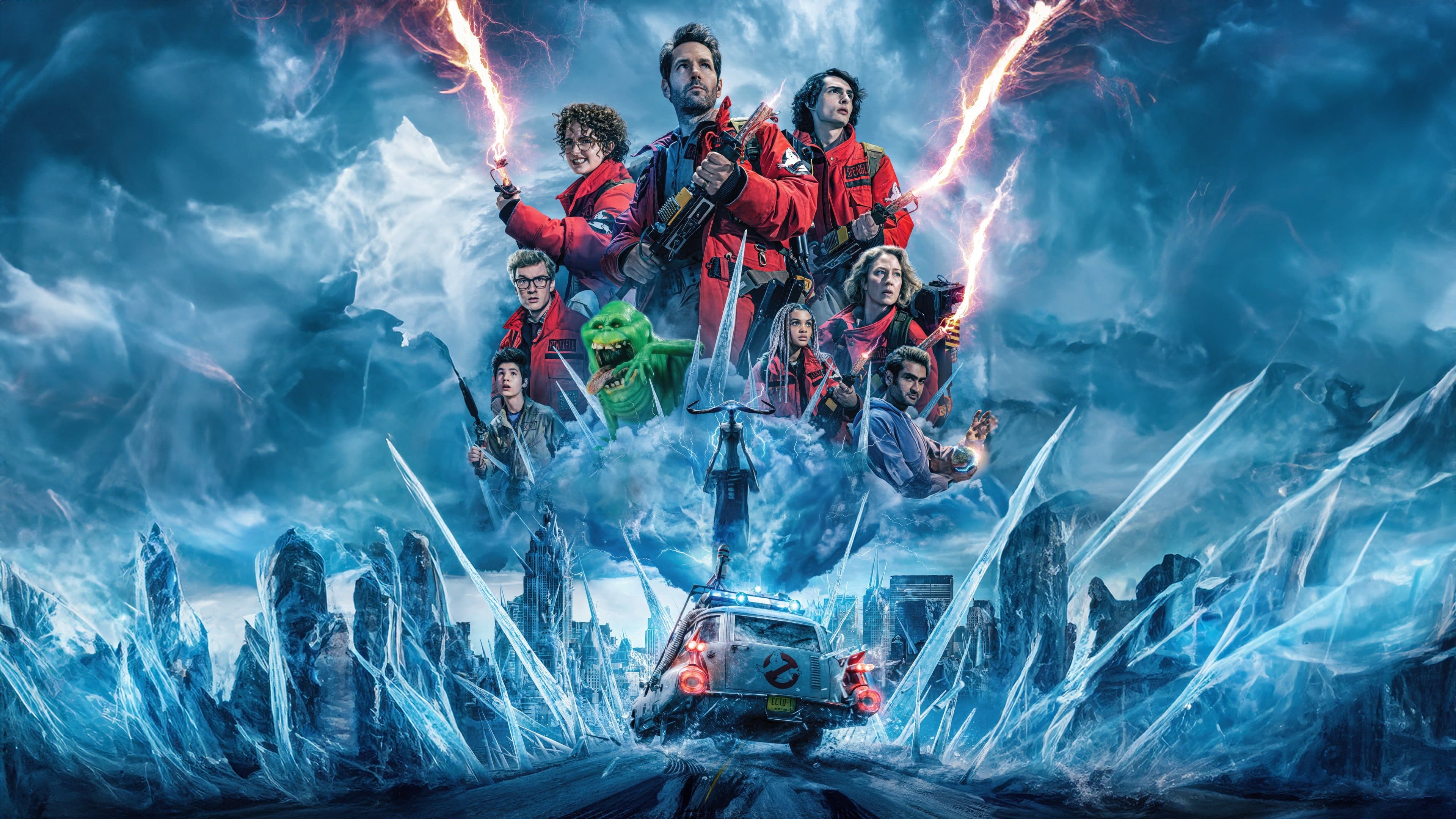

Ghostbusters: Frozen Empire (2024)

The Spengler family returns to where it all started – the iconic New York City firehouse – to team up with the original Ghostbusters, who've developed a top-secret research lab to take busting ghosts to the next level. But when the discovery of an ancient artifact unleashes an evil force, Ghostbusters new and old must join forces to protect their home and save the world from a second Ice Age.

Immaculate (2024)

An American nun embarks on a new journey when she joins a remote convent in the Italian countryside. However, her warm welcome quickly turns into a living nightmare when she discovers her new home harbours a sinister secret and unspeakable horrors.

The First Omen (2024)

When a young American woman is sent to Rome to begin a life of service to the church, she encounters a darkness that causes her to question her own faith and uncovers a terrifying conspiracy that hopes to bring about the birth of evil incarnate.